CA-265 Automatic Edge Banding Machine

Advantage:

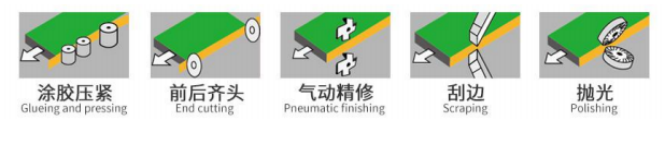

It is suitable for straight edge sealing of solid wood board, fiberboard, particle board and other board workpieces.

The edge sealing materials can be solid wood strips, PVC, melamine, veneer, etc.

1. Equipped with an exquisite thermometer, it is sensitive to temperature and provides accurate heating temperature

in real time.

2. Overvoltage and undervoltage circuit protection, effectively protect the electronic components of the equipment,

and remind customers to provide stable working power.

3. The effect of the edge banding machine is high precision and high efficiency.

4. The End-cutting device moves through precise linear guides, adopts the structure of automatic tracking

of the mold and fast cutting of high-frequency high-speed motor, etc., to ensure that the cut surface is smooth and

smooth.

5. It can be equipped with a double glue pot pressing and sticking system, which can quickly switch between two

colors of glue, and reduce the visibility of the glue line.

Sample:

Parameter Data

Edge band thickness | 0.3-3mm |

Sheet workpiece thickness | 10-60mm |

conveyor belt speed | 16m/min |

Minimum width of sheet | 45mm |

Minimum length of sheet | 70mm |

Total Power | 7kw |

working pressure | 0.6Mpa |

Voltage | 380V (can customize 220v,50/60hz) |