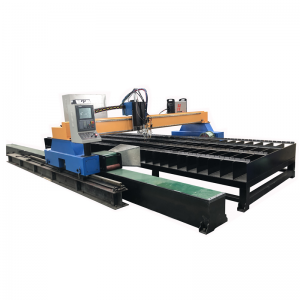

CA-2060 Gantry Plasma&Flame Cutting Machine

Description:

CNC cutting machine is a kind of equipment which dedicated to a variety of carbon steel, stainless steel, aluminum, copper and other metal materials. The equipment in the industrial computer control, adopt high-temperature plasma arc or flame cutting on the plate can be cut in any graphics and text, it is widely used in shipbuilding, pressure vessel manufacturing, machinery manufacturing, steel processing industries.

When using a plasma arc cutting, not only can cut carbon steel, but also cutting stainless steel, aluminum, copper and other metal materials, maximum cutting thickness determined by the plasma source with the decision. Normally, the device used by the U.S. sea treasure produced plasma power, plasma cutting speed relative to the oxyacetylene cutting speed, high efficiency, effectively reduce the overall cost.

When using oxyacetylene or other oxyfuel, only cutting carbon steel, cutting thickness 6 ~ 120mm, such as the use of special cutting torch, cutting nozzle and specialty gases, gas, maximum cutting thickness up to 300mm. Oxyfuel cutting, plasma cutting with respect to the slow, but a thick steel plate can be cut, and the use of low cost.

The device mechanical structure gantry form, from the main end beam, secondary-side beams, and beams composed of portal frame, driven by AC servo motor, walking on the rails. CNC cutting trolley through the slider fixed to the beam front, driven by a servo motor, through the gear rack drive, walk by the linear guides.

The device is also equipped with automatic torch height adjustment device and automatic arc ignition device, the use of automatic nesting software programming, enabling automatic control of the cutting process.

Equipment used graphics file programming language international common CNC Programming Language – G code language. G-code file can be edited manually, or use the device supporting FASTCAM automatic nesting software programming or other programming software for automatic programming and nesting, easy programming, sheet utilization.

Specification:

1. The machine body

It is gantry type structure. The cross beams treated by whole annealing to eliminate stress so it has good rigidity and high strength without permanent deformation.

2. The vertical rails

The vertical guide track adopts heavy rails. The surface has high precision after grinding . The rail length can be increased and decreased according to the requirements of users;Rails using 38Kg / m rail processed from the top surface and the side after grinding with high straightness and parallelism; foundation generally use concrete structure ( also available in steel ).

3. The cutting torch holder

The cutting torch holder adopts the collision-preventing design to ensure the cutting torches are not damaged in production.

4. The horizontal rails

The horizontal guide track adopts a straight line track with high precision and smooth running.

5. The driven system

The driven device adopts Stepper motor and driver (Japan Panasonic Servo motor optional) which has high running precision.

6. Regulator of auto height regulator

The machine has many functions such as automatic position, automatic perforation, and automatic height-regulating device of capacitance. The plasma cutting machine is equipped with USA imported arc voltage height-regulating device.

7. The track gauge

The machine with below 4m gauge adopts single side driven, the machine with above 4m gauge adopts double-side driven to guarantee its precision and high speed smooth running.

Parameters:

| Model | CA-2060 |

| Cross Beam width | 2500mm(Can be widen according to user’s demand) |

| Longitudinal Rail Length | 8000mm(Can be lengthened according to user’s demand) |

| Effective Cutting Width (X axis) | 2000mm |

| Effective Cutting Length (Y axis) | 6000mm(Rail can be lengthened according to user’s demand) |

| Cutting Mode | Plasma+Flame |

| Drive Mode | Dual-side |

| Drive Method | Rack and pinion drive for X and Y axes |

| Flame Cutting Thickness | 6-200mm |

| Plasma Cutting Thickness | 0.3–25mm( Depends on plasma power source capacity) |

| Traveling speed | 20000mm/min |

| Cutting Speed | 0-12000mm/min |

|

Repeatability |

+-0.05mm |

| Power Source | 380V 50/60Hz |

| Power capacity | 25-50KW according to different power source |

| Cutting Gas | Acetylene,Propane,oxygen |

| Plasma Gas | Pressed air,Oxygen,N2 |

| Cutting Thickness |

(63A)0.3-8mm |

| Brand:LGK/US-Cutmaster/US Hypertherm optional) |

(100A)0.5-12mm |

|

(120A)0.5-16mm |

|

|

(160A)0.5-20mm |

|

|

(200A)0.5-25mm |

|

|

(400A)0.5-40mm |

|

|

(600A)0.5-50mm |