CA-1625 CNC Oscillating Digital Cutter

Features:

1. The platform detection device regulates the knife pressure automatically, enabling a level platform and perfect cutting.

2. The high precision CNC oscillating knife leather cutting machine can induce draft separately and easily cuts small pieces.

3. The anti-collision and the built-in auto-sensing devices ensure the security of cnc oscillating knife leather cutting machine.

4. High efficiency can be realized without making a high-cost knife model.

5. The high precision CNC oscillating knife leather cutting machine is designed for production with small quantities and can save on costs while maintaining speed and accuracy.

Parameters:

| Parameter/Model |

CA-1625 |

CA-2030 |

| Multi-functional Cutting Head | Replaceable oscillating knife, half knife, full knife, oblique knife and creasing wheel etc. | |

| Tools configuration | Various cutting tools, creasing wheels, pen, cross positioning laser | |

| Safety | High sensitivity infrared induction (optional) | |

| Moving Speed | Max. 1500mm/s | |

| Cutting Speed | Max. 800mm/s(please set the speed according to the material) | |

| Material Applicable | Corrugated paper,non woven fabric , PVC expansion sheet, KT board, foam board, grey paperboard, cardboard, vehicle sticker, adhesive sticker etc. | |

| Cutting Depth | Max 50mm (depends on the material) | |

| Material Fixing Method | Strong power vacuum absorption and intelligence Partition | |

| Resetting Positioning Accuracy | Max 0.01mm | |

| Mechanical Precision | Max 0.02mm | |

| motor | Taiwan Delta servo motor | |

| Control System | Ruida control system | |

| Data Transmission | Ethernet | |

| Command format | Dxf/plt/bmp/gif/jpge/cdr/dmg/pwj | |

| Pump voltage | AC 220V +38V | |

| Pump Power | Intelligent vacuum pump 9kw | |

| Max Working Size | 2500*1600mm | 3000*1800mm |

| Machine working voltage | AC220V/380V | |

| Body dimension | 3050*1950*1355mm | 3550*2250*1235mm |

| We reserve the final explanation for the above parameters and able to make any alternations without notice | ||

Advantages:

1) Intelligent table surface error compensation: Select high-precision measuring instruments to accurately compensate the cutting accuracy of each point.

2) Optional function: multi-head double gantry, double the efficiency.

4) Continuous cutting system: intelligent material discharge, continuous cutting, and optional receiving table.

3) Tool quick change module: simple and efficient tool holder quick change system, making operation easier and convenient

4) Partition adsorption function: Intelligent partition tracking adsorption system, local suction is greatly increased.

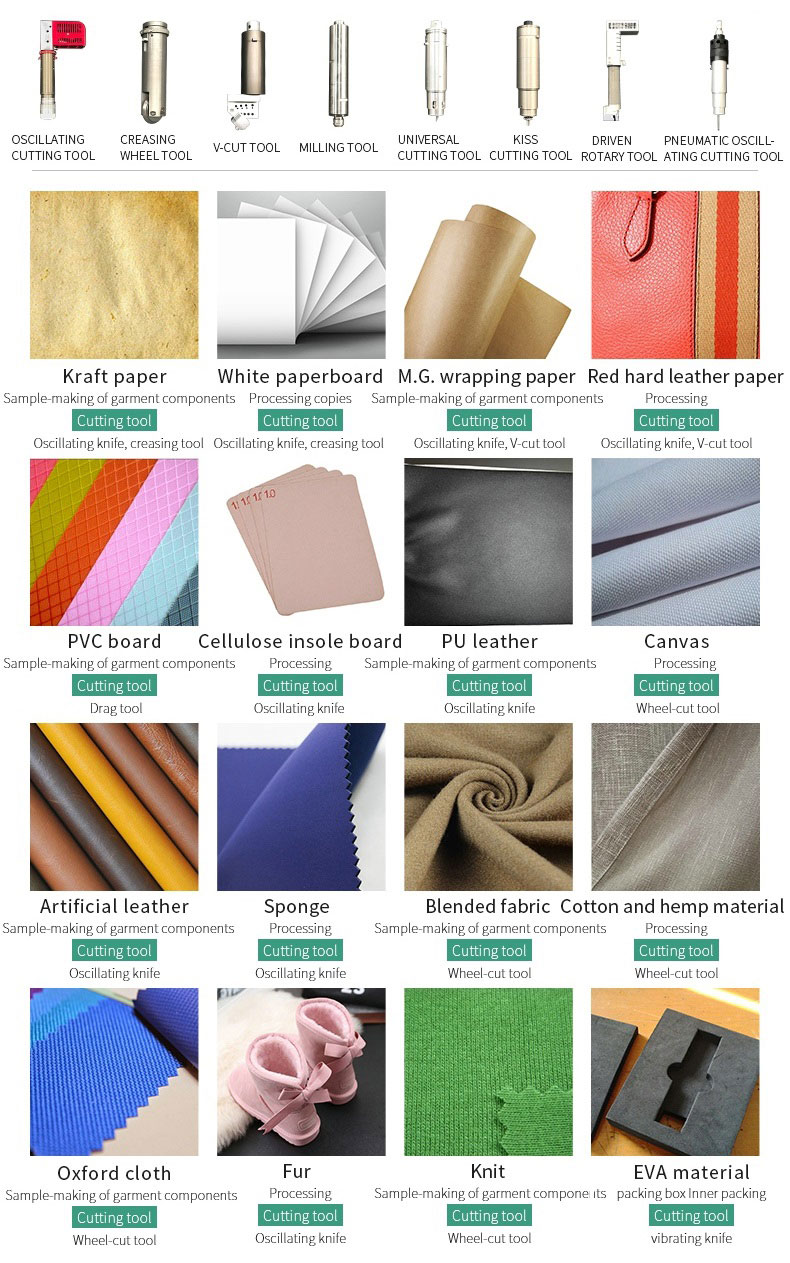

Tools&Samples: