CA-2513 Side Hole Wood Drilling Machine

Introduction:

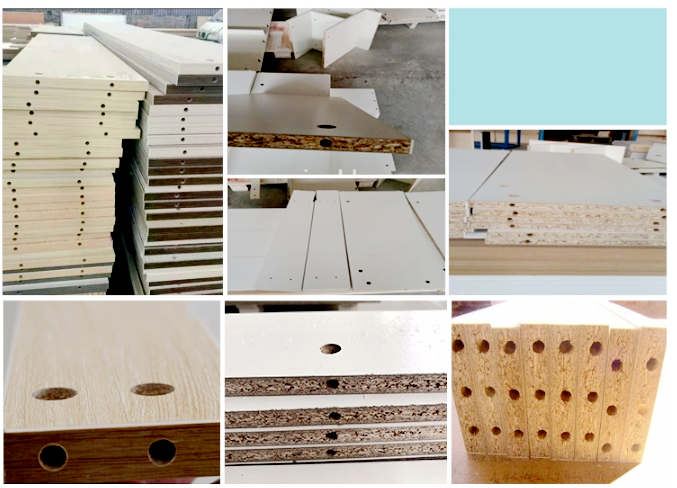

CNC side drilling machine is a numerical control model developed for the side hole drilling of panel furniture.

At the same time, the machine can change between long & short boards, wooden boring holes, single holes and blind holes to meet varieties of process requirements for each workshop.

Application:

The furniture industry: cabinets, doors, panel, office furniture, doors and windows and chairs

Wood products: speakers, game cabinets, computer tables, sewing machines, musical instruments

Decoration industry: Acrylic, PVC, MDF, artificial stone, glass, plastic, and copper and aluminum and other soft metal sheet cutting engrave.

Advantage:

This machine adopts steel structure, seamless welding, annealing and heat treatment to make the fuselage be hard.It adopts American

1. With the intelligent furniture design and production software perfectly combined to truly achieve intelligent production. High precision and speed.

2. The whole machine is welded seamlessly with 10mm thick wall rails.

3. Use imported linear guides, double rail design, low resistance, high precision.

4. The servo drive has high transmission power and tilted rack drive for more stable operation and higher precision.

5.Support long material, short material, long groove, three-hole drilling processing mode.

6.One set of side drilling machine can work well with two or three sets CNC Router.It is easily to solve the horizontal drilling problem

Technical Parameters:

|

NO. |

Description |

Parameter |

|

1 |

Maximum processing length |

2650mm |

|

2 |

Spindle |

2.2kw air cooling spindle |

|

3 |

Spindle speed |

0-24000RPM/MIN |

|

4 |

traveling speed |

150M/MIN |

|

5 |

Process speed |

105M/MIN |

|

6 |

Control system |

Customized BEST system |

|

7 |

Driver and motor |

exclusive custom double servo motor 750W/400W |

|

8 |

Inverter |

Best inverter |

|

9 |

Z movement |

Pneumatic cylinder |

|

10 |

Main Function |

Three-hole in one / wood pin hole / slot |

|

11 |

Overall Dimension |

3350*1770*1400mm |