Maintenance of mechanical parts

1. Maintenance of tool magazine and tool change manipulator

① When manually loading the tool into the tool magazine, ensure that it is in place and check whether the locking on the tool holder is reliable;

② It is strictly forbidden to load overweight and overlong tools into the tool magazine to prevent the robot from changing the tool or collision between the tool and the workpiece, fixture, etc.;

③ When using sequential tool selection, pay attention to whether the order in which the tools are placed on the magazine is correct. Other tool selection methods should also pay attention to whether the number of the tool to be changed is consistent with the required tool to prevent accidents caused by changing the wrong tool;

④ Noted to keeping the knife handle and sleeve clean;

⑤ Frequently check whether the zero return position of the tool magazine is correct, check whether the position of the machine spindle return tool change point is in place, and adjust it in time, otherwise the tool change action cannot be completed;

⑥ When starting up, the tool magazine and manipulator should be run dry first to check whether each part works normally, especially whether each travel switch and solenoid valve can operate normally.

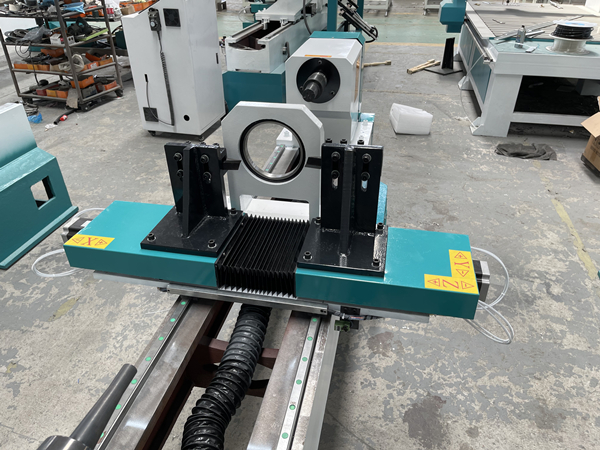

2. Ball screw maintenance

① Regularly check and adjust the axial clearance of the screw nut pair to ensure the accuracy of the reverse transmission and the axial rigidity;

② Regularly check whether the connection between the screw support and the bed is loose and whether the support is damaged. If there are any of the above problems, tighten the loose parts in time and replace the support bearings;

③ For ball screws with grease, clean the old grease on the screw every six months and replace with new grease. The ball screw lubricated with lubricating oil should be refueled once a day before the machine tool works;

④ Take care to prevent hard dust or chips from entering the lead screw guard and hitting the guard during work. If the guard is damaged, it should be replaced in time.

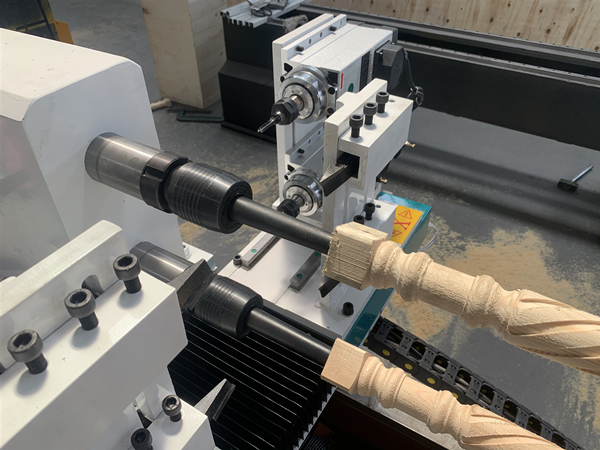

3. Main drive chain maintenance

① Regularly adjust the tightness of the spindle drive belt;

② Prevent all kinds of impurities from entering the fuel tank. Change the lubricating oil once a year;

③ Keep the connecting part of the spindle and the tool holder clean. It is necessary to adjust the displacement of hydraulic cylinder and piston in time;

④ The counterweight should be adjusted in time.

4. Hydraulic system maintenance

① Filter or replace oil regularly;

② Control the temperature of the oil in the hydraulic system;

③ Prevent leakage of hydraulic system;

④ Check and clean the oil tank and pipeline regularly;

⑤ Implement the daily point inspection system.

5. Pneumatic system maintenance

① Remove impurities and moisture from compressed air;

② Check the oil supply of the lubricator in the system;

③ Maintain the tightness of the system;

④ Pay attention to adjusting the working pressure;

⑤ Clean or replace pneumatic components and filter elements;

Post time:August-04-2021