The functions of the rotary axis on cnc router?

1. Calculate the rotation engraving path without unfolding the surface;

2. There is no need to rotate the workpiece repeatedly; the tool path calculation is completed at one time.

3. Reduce the finishing allowance; the tool path can be roughed in layers.

4. Realize partial rotation processing; the angle range and length range can be set.

5. Affected by the accuracy of the fixture, the machining of irregularly rotating workpieces usually adopts multi-face rotation positioning machining. There are always seams between different machining directions.

6. Rotary engraving processing without positioning joints adopts the integral method of rotating shaft, and the engraving machine generates an automatically closed rotary engraving processing path.

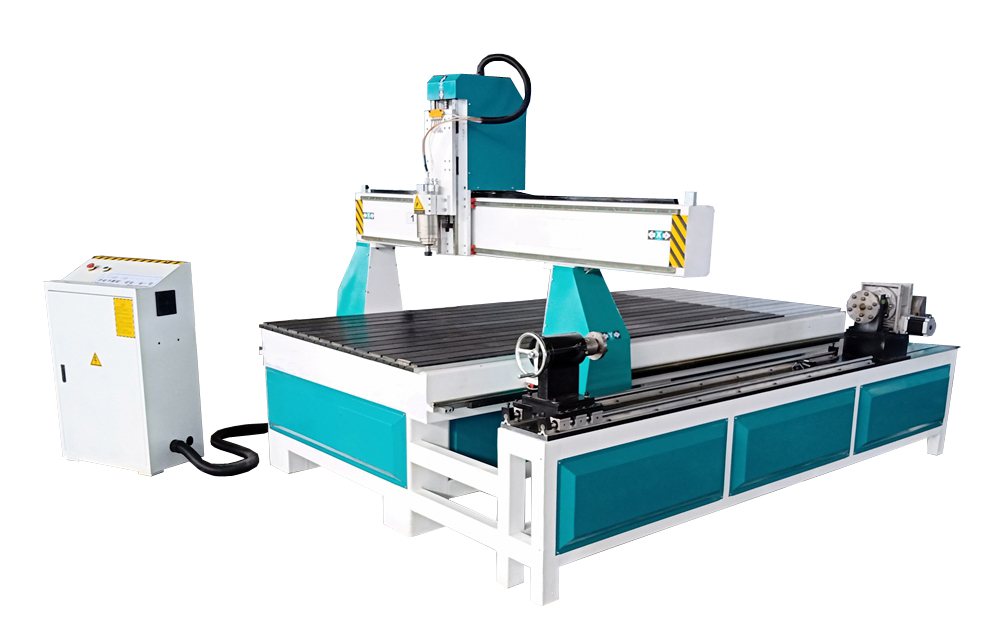

How to use the rotary axis?

1. Put it directly on the platform, so that the gantry needs to be heightened, and the size of the platform will not affect the plane carving. The rotating shaft can be put on and taken down at any time.

2. Put the side of the platform, the diameter of the rotating shaft affects whether the gantry is heightened. If the diameter is large, the gantry needs to be heightened. If the diameter is less than 100mm, it is not necessary. However, placing the rotation axis on the side will affect the size of the platform, and sometimes the gantry needs to be widened.

3. The table top sinks, the table top sinks as a whole, put the rotation axis under the platform, if you engrave the plane, put the platform on the rotation axis for carving.

Is it better to calculate by perimeter or by angle?

We suggest that it is more convenient to calculate by angle, so that you don’t need to adjust the parameters every time. If the diameter changes according to the circumference, you need to recalculate the pulse equivalent.

Post time:May-19-2021