To understand the difference between 3 and 5-axis routers, you first have to understand how CNC routers work and some of their basic components. Once you have this background knowledge you will be able to determine which type of routerbest suits your needs.

How a router works

The power behind any router is its CAD/CAM software. The CAD software allows the user to create a design they want the router to cut. Once this design has been made, the CAM software converts the design into a tool path code that the router can understand.

The computer then translates this code into signals that control the movement of the router’s drive system. The drive system contains the spindle, which is the part that holds the actual router bits. The spindle rotates these bits 8,000 to 50,000 times per minute in order to cut the material. Simply put, the user creates a design and uses software to make instructions for the router to follow.

3-axis routers vs. 5-axis routers

Now that you have a working knowledge of how a router works you can better understand the differences between various models. Although 4-axis routers exist, the most common CNC routers available are 3 and 5-axis routers.

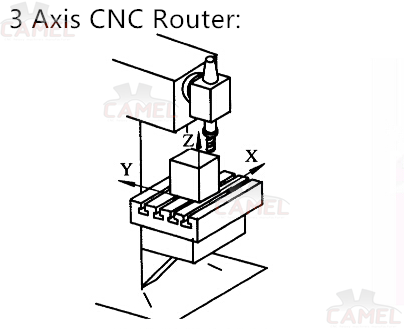

3-axis CNC routers cut along three axes at the same time; the x-axis, the y-axis, and the z-axis. Cutting along the x-axis moves the router bit from front to back, cutting along the y-axis moves it from left to right, and cutting across the z-axis moves it up and down. These machines are used primarily for cutting flat, 2-dimensional parts.

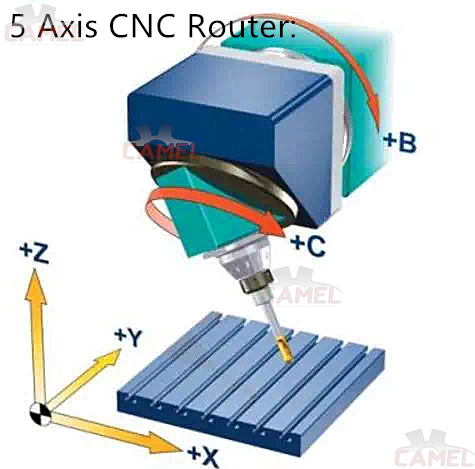

5-axis CNC routers can cut along two additional axes than 3-axis routers. These routers have the ability to cut on five sides of a piece of material simultaneously, which expands the operator’s capabilities and flexibility. Unlike their 3-axis counterparts, these machines are usually used to cut large 3-dimensional parts. In addition, 5-axis routers have a taller gantry and longer x-axis, which allows them to cut larger part; however, this comes at a serious cost; the taller the gantry and the longer the x-axis, the less the accurate and stable these machines are. For proper quality control, the height of the gantry and the length of the x-axis should be limited as much as possible.

Post time:November-21-2019