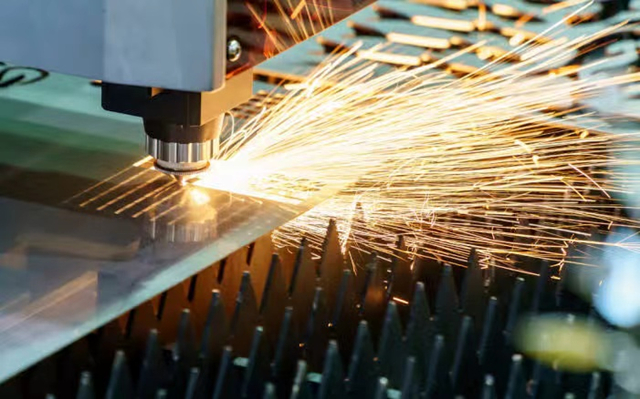

The laser cutting machine is to focus the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material will finally form a slit, so as to achieve the purpose of cutting.

Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting patterns, automatic typesetting, saving materials, smooth cuts, and low processing costs. It will be gradually improved or replaced. Traditional metal cutting process equipment.

So, how should we choose a fiber laser cutting machine?

Precautions for purchasing fiber laser cutting machine::

To put it simply, there are three points to pay attention to when choosing a fiber laser cutting machine: 1. The company’s technical strength 2. The quality of product equipment 3. After-sales service support.

If the company’s technology and strength do not work for a long time, don’t talk about after-sales service. Secondly, the quality of product equipment is mainly reflected in several aspects, including product configuration, machine tool workmanship and assembly technology. The configuration is now more selective and there are only imported and domestic lasers, and the price is also quite different. Machine tool workmanship and assembly technology are very important, which determine the stability, accuracy and life of the machine in the future, and determine the overall quality and performance of the equipment.

Our company is equipped with professional R&D technicians, committed to laser machine production, innovation and various technological breakthroughs to ensure that each machine meets the highest standards.

In addition, price is also an important factor in choosing a suitable fiber laser cutting machine, and cost-effectiveness has always been the pursuit of every customer. Therefore, when you are choosing a machine, please inform our sales staff of your budget, and they will recommend the most cost-effective machine for you.

Fiber laser cutting machine is suitable for a variety of industries, and customers can choose according to their processing industries. Machinable materials include: stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, aluminized zinc sheet, pickling sheet, copper, silver, gold, titanium and other metal plates and pipe cutting. Fiber laser cutting machine industry is used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tools Processing, decoration, advertising, metal external processing, kitchenware processing and other manufacturing and processing industries.

Post time:November-11-2021