How to adjust the optical path of the laser cutting machine? Many novice customers are still relatively unfamiliar with the operation of adjusting the optical path after purchasing a laser cutting machine, but laser cutting machine manufacturers will provide training services for customers. However, there are also many customers who forget the operation method very quickly. Therefore, here, High Energy Laser has compiled a tutorial on the adjustment of the optical path of the laser cutting machine for everyone to share.

Why do I need to adjust the light path?

The laser cutting machine itself uses a flying optical path system. During long-term work, the optical path will be slightly deviated, which will have a great impact on the cutting effect. Therefore, it is very necessary to check the light path and adjust it regularly. Before adjusting the optical path of the laser cutting machine, we must have enough knowledge of the laser tube, the reflecting mirror frame and the focusing lens. Let’s introduce it to you first.

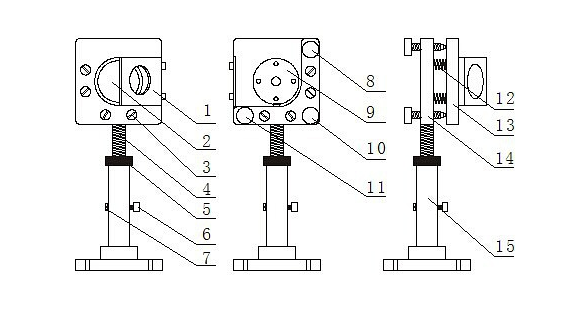

1>. Mirror frame A

1. Light target placement frame 2. Mirror 3. Tension spring locking screw 4. Adjusting screw 5. Adjusting nut 6. Locking screw a7. Locking screw b 8. Adjusting screw M1 9. Mirror locking piece 10. Adjusting screw M 11. Adjusting screw M2.12. Tension spring 13. Mirror mounting plate 14. Support plate 15. Base.

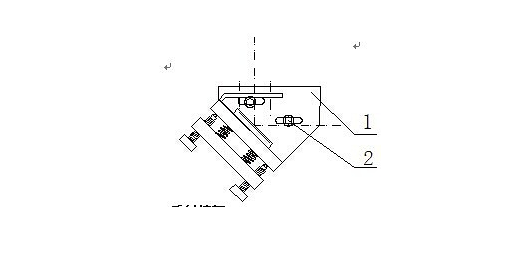

2>. Mirror frame B (the mounting base plate is different from that of frame A, but the rest are the same).

1. Install the bottom plate (movable left and right). 2. Tighten the screws

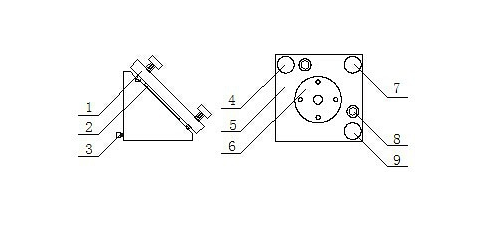

3>. Mirror frame C

1. Mirror adjustment plate 2. Mirror 3. Locking screw 4. Adjusting screw M1 5. Mirror adjusting plate 6. Mirror pressing plate 7. Adjusting screw M 8. Locking screw 9. Adjusting screw M2

4>. Focusing lens

1. Focusing lens inner tube 2. Air inlet pipe 3. Limiting coil 4. Air nozzle transition sleeve 5. Air nozzle 6. Lens tube 7. Limit screw 8. Adjusting sleeve.

Understanding the names of the various parts, let’s teach you how to adjust the optical path of the laser cutting machine:

(One)

(1) For the adjustment of the first light, use masking paper to stick to the dimming target hole of the reflector A, manually click the light (note that the power should not be too large at this time), and fine-tune the base of the reflector A and the laser tube Bracket, so that the light hits the center of the target hole, pay attention to the light can not be blocked.

(2) To adjust the second light, move the reflector B to the remote, use a piece of cardboard to emit the light from near to far, and guide the light into the cross light target. Because the remote light is inside the target, the near end must be inside the target, and then Adjust the near end and remote spot to be the same, that is, how far the near end is, and how far the far end is, so that the cross is in the same position in both the near end and the remote spot, that is, near (far), indicating the light path and the Y-axis guide rail. parallel.

(3) Adjust the third light (note: the cross bisects the spot left and right), move the reflector C to the remote, guide the light into the light target, shoot once at the entrance and remote, and adjust the position of the cross to be close The position of the cross in the end spot is the same, which means that the beam is parallel to the X axis. At this time, the light path is in or out, you need to loosen or tighten the M1, M2, and M3 on the frame B until the left and right halves.

(4) To adjust the fourth light, use a piece of masking paper to stick to the light outlet, make the light hole leave a circular mark on the adhesive paper, click on the light, remove the adhesive paper to observe the position of the small hole, adjust the mirror as appropriate M1, M2, and M3 on frame C until the spot is round and straight.

(2) The method of measuring the focal length: use the focal length scale provided by our laser cutting machine manufacturer, move the nozzle up and down and place it on the number 5 of the focal length scale. At this time, the light is the brightest and strongest, and then tighten the screw.

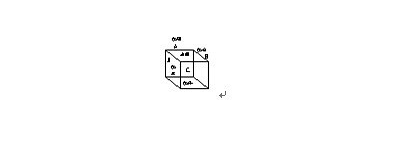

(三) Shown as four squares (pictured)

(1) The cutting surface is shifted to the left, the laser head is too low or the vertical light reflector is too high. If the icon is inclined to the D surface, the light is low. Two solutions: 1. Lower the vertical light reflector C and set M1 , M2 and M3 rotate counterclockwise at the same time; 2. Raise the laser tube (clockwise) (2) The cutting surface is shifted to the right, the laser head is too high or the vertical light reflector C is too low. High, two solutions: 1. Raise the vertical light reflector C, turn M1, M2, and M3 clockwise at the same time;

2. Lower the laser tube (counterclockwise) (3) The cutting surface is offset, the laser enters the vertical light The reflector is outside or the reflector holder B is outside. For example, the icon is inclined to the A side, indicating that the light path is outside. Two solutions: 1. Adjust the reflector holder B, 2. Set the M1, M2 on the reflector B M3 is adjusted at the same time (clockwise) (4) The cutting surface is out of the way, and the laser enters the vertical beam mirror or the reflector holder B. If the icon is inclined to the C surface, it means that the light path is inward. Two solutions: 1 , Call out the mirror seat B, 2. Call out M1, M2, and M3 on the mirror B at the same time (counterclockwise).

Post time:April-29-2021