I. Occupational hazards that may occur when operating a CNC plasma flame cutting machine: flame splash, gas shock, high-voltage electric shock, mechanical damage.

II. In order to ensure the safe production of CNC plasma and flame cutting machines, the safety protection measures that the operator must take:

1. The operator must undergo special safety technical training in accordance with the regulations and obtain the corresponding qualification certificate. 2. Before operation, check the electricity/gas source, water source, and electricity/air pressure (replace the new gas in time when the output pressure of the oxygen cylinder is lower than 0.1MPa) , Whether the PE line is normal.

3. Check whether there are flammable and explosive materials (including gas vessel pipelines with flammable and explosive gases) within 10m on both sides of the guide rail near the equipment.

4. The operator must wear ppe (personal protective equipment-work clothes, protective glasses, respirators, etc.) correctly

5. The operator must strictly abide by the safe operation rules of general welders, manual gas welding (cutting) workers and the safe use rules of rubber hoses, oxygen cylinders, and various industrial cutting gas cylinders and the safe operation rules of welding torches.

III. Safety operating procedures:

1. Before turning on the machine, check whether there are debris around the machine, on both sides of the guide rail and the operating platform, no flammable items within 10 meters, and whether the air, water, and power sources used are in normal working conditions.

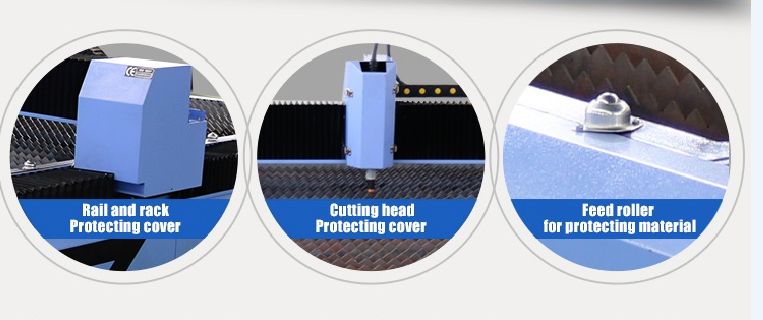

2. Check whether the grounding related to the machine tool is loose, and whether each cable connector socket is intact. Check the joints of the gas cylinder and the rubber hose, the valves and fasteners should be fastened firmly, no looseness, damage and air leakage are allowed, check the rack and bed of the guide rail. Check the material and the torch anti-collision device.

3. During the operation of the machine tool, the body parts are strictly prohibited to touch the moving parts of the machine to avoid injury. Turn off the power and stop when repairing and maintaining the equipment.

4. It is forbidden to use oily tools, gloves, etc. to contact the oxygen cylinder and its accessories, valves, and rubber hoses. It is forbidden to use tools prone to sparks to open the oxygen cylinder or acetylene gas valve (the equipment specifically uses gas).

5. In the event of an unexpected power failure, the main power switch should be turned off in time.

6. When gas cylinders or busbars (for multiple cutting torches) pipes are frozen, it is strictly forbidden to use fire roasting or knocking with tools. Oxygen valves or pipes can be melted at a water temperature of 40°C. Gas cylinders should be protected from direct sunlight and fall prevention measures.

7. It is forbidden to dismantle the automatic ignition control device or automatically cut off the burner when electrified to prevent high-voltage electric shock. The power supply must be turned off when replacing. Regularly check whether the plasma cable is exposed, damaged or aging, and the replacement of the cable should be carried out by the relevant personnel (the person responsible for equipment maintenance).

8. It is forbidden to place metal objects on the guide rail surface, working surface, and paint surface of the cutting machine, and it is not allowed to knock, straighten and trim the workpiece on it.

9. It is strictly forbidden to set and adjust CNC program files and process parameters privately (which needs to be carried out by a technician). After inputting a new part program, it should be trial run first, and its operation should be checked, and then put into operation after confirming that it is correct.

10. When alarms and other unexpected failures occur during operation, press the pause button to stop the operation in time, and then perform corresponding operations. The emergency stop button should be avoided as much as possible. If you cannot handle it by yourself, you need to report to the superior and the person in charge will handle it.

11. When lifting and transporting the work piece, you should closely cooperate with the operator, pay attention to avoid the collision between the lifting object and the equipment, and follow the “lifting, mover” safety operation rules when loading and unloading.

12. Before shutting down after get off work, the system should be returned to the main operating menu, the cutting torch should be raised to the highest position, and all control switches should be reset. Turn off the system power first, then turn off the main power supply, turn off the air and water sources, check whether the control handles are in the closed position, and check and clean up the site. Only after the extinction of the fire is confirmed, can you leave.

Post time:April-20-2021