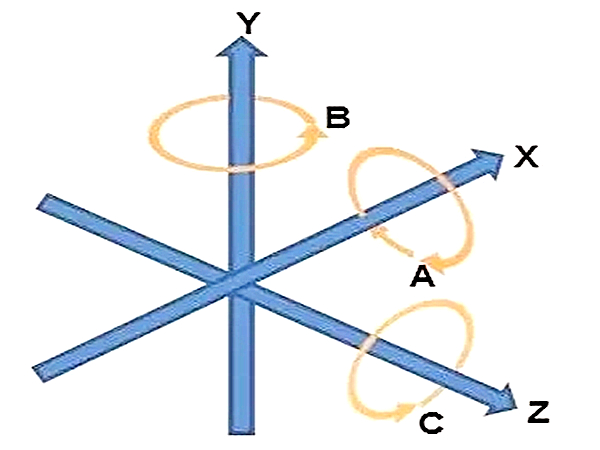

First we make a clear understand that the standard nomenclature for the basic 9 axis are:

X,Y,Z are linear axes where Z is aligned with the spindle of the machine.

A,B,C are rotary axes rotating around XYZ respectively.

U,V,W are parallel linear axes along XYZ respectively.

2-axis Lathe

With only 2-axis, XZ, the standard lathe is incredibly versatile. You can turn round parts, both inside and outside.

3-axis Lathe

The third axis (Y) is perpendicular to X and Z, allowing for curves to be machined. Driven by ball screw actuators, the Y-axis slide on linear guides or box ways.

The motion is obtained by moving the tool in additional ways. Some machines have multiple tool positions and live-tool pockets on the turret, driven by a motor. The turret is mounted on the carriage or cross slide.

Others may have a dedicated milling tool driver mounted on a turret face. A larger motor is required for this automatic toolchanger with a capacity for as many as 30 tools. Yet others mount the Y-axis ways on a slant bed.

Other manufacturers mount an independent milling head with tool change capability. Still others mount an independent milling head with tool change capability.

4-axis Lathe

For live tooling to be effective, it is necessary to orient the workpiece accurately. This is accomplished by a spindle or rotary C-axis.

Tiny servomotors in the tooling mounted on the turret comes into play when the main spindle stops rotating, converting the lathe into a conventional milling machine. Using servomotors to hold position will allow for both positioning and contouring motion. Profiling cuts can be made in this way, by using simultaneous X-Y-Z-axes motion with the C-axis.

5-axis Lathe

The fifth axis is usually the A or B axis, so the machine has either an XYZAC or XYZBC toolpaths.

The B-axis capability sets the 5-axis machine apart from the previous four. The axis rotates about the Y axis, making cuts with compound angles possible. The 5-axis machine supports the entire range of milling and turning operations, making it possible to do all milling and turning operations in one setup.

When you chose a machine,its better to show your sample pictures ,professional CAMEL CNC sales will recommend the most suitable machine mdoel for you.

Post time:October-28-2020